Manufacturing method of sausage filling machine

The utility model relates to the field of food production machinery, in particular to a sausage filling machine.

Background technique:

As a delicious food, sausage is loved by many people. Sausage filling machines are common in small workshops. At present, traditional sausage filling generally uses a meat grinder and a filling machine. At the end, the casing enters the casing under the action of gravity to achieve the filling effect, the filling efficiency is relatively slow, and during the filling process, the operator needs to grasp the casing by hand for filling, which increases the workload of the operator.

Technical realization elements:

In order to solve the above problems, the present utility model provides a sausage filling machine, which is driven by a motor to rotate a reciprocating screw rod. The reciprocating motion of the push rod can make the minced meat enter the filling tube for filling more quickly. The filling efficiency is compared. It is high, and the casing fixing seat and the filling tube are matched to fix the casing, eliminating the labor of the operator to fix the casing manually and reducing the amount of labor. In order to achieve the above technical purpose and meet the technical requirements, the present utility model adopts the following technical solutions To achieve.

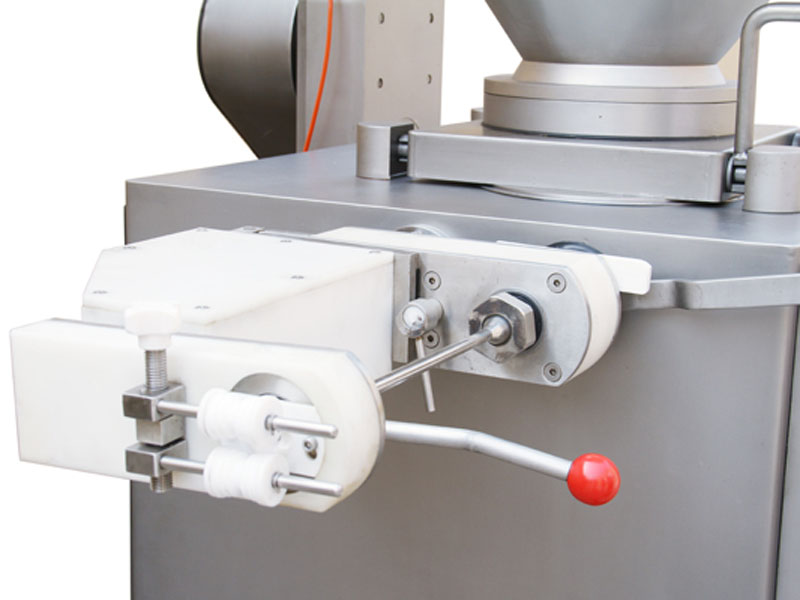

A sausage filling machine, which is characterized in that it comprises a meat grinder and a frame body, the meat grinder is fixedly connected to the top surface of the frame body, and the meat outlet of the meat grinder is arranged on the left side; the frame body is A cuboid cavity, the lower surface of the top plate of the frame body is rotatably connected with a driven gear, the center of the driven gear is fixedly connected with a reciprocating screw, the reciprocating screw is threadedly connected with a push rod, and the side of the push rod is provided with a symmetrical track, The rails are provided with sliders, and the sliders are also fixedly connected to a first fixed rod and a second fixed rod. The first fixed rod is an L-shaped rod. The other end of the first fixed rod is connected to the top plate of the frame. The lower surface is fixedly connected, the second fixed rod is a Z-shaped rod, the other end of the second fixed rod is fixedly connected to the inner surface of the right side plate of the frame body, and the upper part of the inner surface of the right side plate of the frame body is fixedly connected with a motor, The rotating shaft of the motor is fixedly connected with a driving gear, the driving gear meshes with the driven gear, the lower part of the frame body is provided with a meat collecting plate, the lower part of the meat collecting plate is provided with a filling mechanism, and the filling mechanism includes The filling tube and the casing fixing seat, the filling tube and the meat collecting plate are fixedly connected and communicated, the filling tube is collinear with the axis of the push rod, the bottom of the filling tube is provided with an annular chute, and the filling tube The bottom of the tube is also provided with a ring-shaped first fixing table, the casing fixing seat includes a connecting pipe corresponding to the sliding groove, and the bottom of the connecting pipe is provided with a ring-shaped second fixing table, the second fixing table is evenly hinged in the circumferential direction There are fixed parts.

Further, the upper part of the meat grinder is provided with a meat bucket, and the meat bucket is in the shape of a rounded platform.

Further, the length of the track is consistent with the ascending and descending strokes of the reciprocating screw rod.

Further, the diameter of the push rod is slightly smaller than the inner diameter of the filling tube.

Further, the meat collecting plate is fixedly connected to the side of the frame body with four pieces, and the meat collecting plate is arranged obliquely to the ground and has the same inclination angle in the clockwise direction as the ground.

Further, the inclination angle between the meat collecting plate and the ground is 30-45°

Further, a receiving plate is provided under the filling mechanism.

The beneficial effect of the utility model is that the structure is novel and the function is practical. The reciprocating screw rod is driven to rotate by the motor. The reciprocating motion of the push rod can make the minced meat quickly enter the filling tube for filling. The filling efficiency is relatively high, and the casing The fixing seat and the filling pipe can be matched to fix the casing, eliminating the labor of the operator to fix the casing manually and reducing the amount of labor.